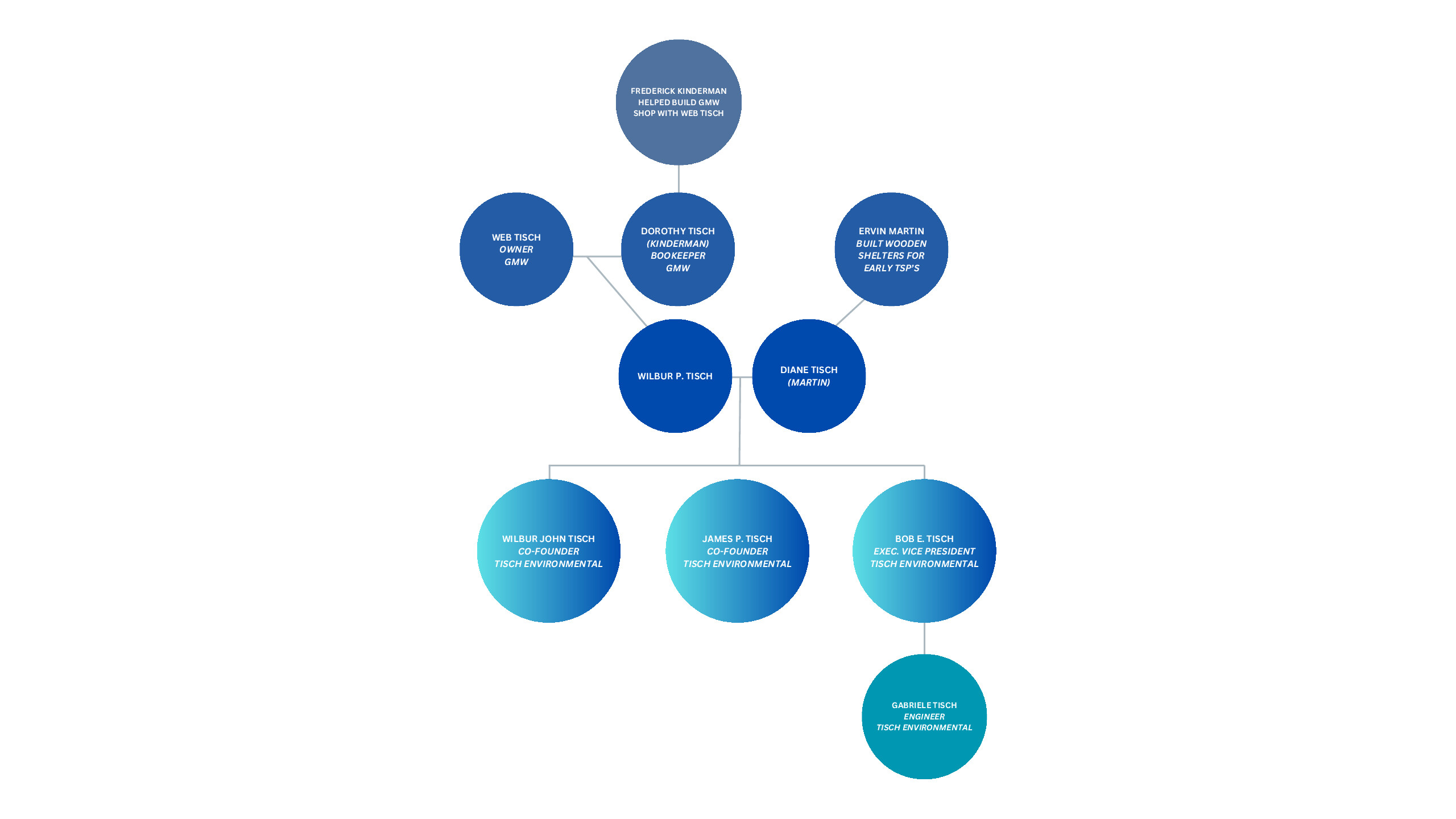

By: W. John Tisch (John), Co-Founder of Tisch Environmental

with details provided from: my Father Wilbur P. Tisch (Will) & Grandfather Wilbur H. Tisch (Web)

The Tisch family has been involved in the manufacture of air sampling equipment for 70 years. Long ago there was a small sheet metal shop, General Metal Works, Inc. (GMW) owned by Mr. William Hasse operating in Greendale, Indiana only eight miles from where I sit. My Grandfather Web worked there as a sheet metal fabricator for 6-8 years when Mr. Hasse died suddenly. His wife wanted to sell the business and Web, being at the right place at the right time, worked out a deal to buy GMW in 1954. Web along with my Dad’s maternal Grandpa Fredrick Kinderman, a retired brick layer, staked out a place in their side yard, bought building materials and built a new shop on the same lot as their home. The shop was said to be only 40’x40’ or 1600 SF. Over time, and a couple of additions, the building reached 3200 SF. Grandma Dorothy Tisch was the homemaker as well as the company bookkeeper. Dad started his first job with GMW at the age of fourteen and worked until he retired from Tisch Environmental at the age of 80. Side note: In January of 2006, Tisch Properties, LLC was able to purchase the original family-built shop and currently leases it to Delta Propeller.

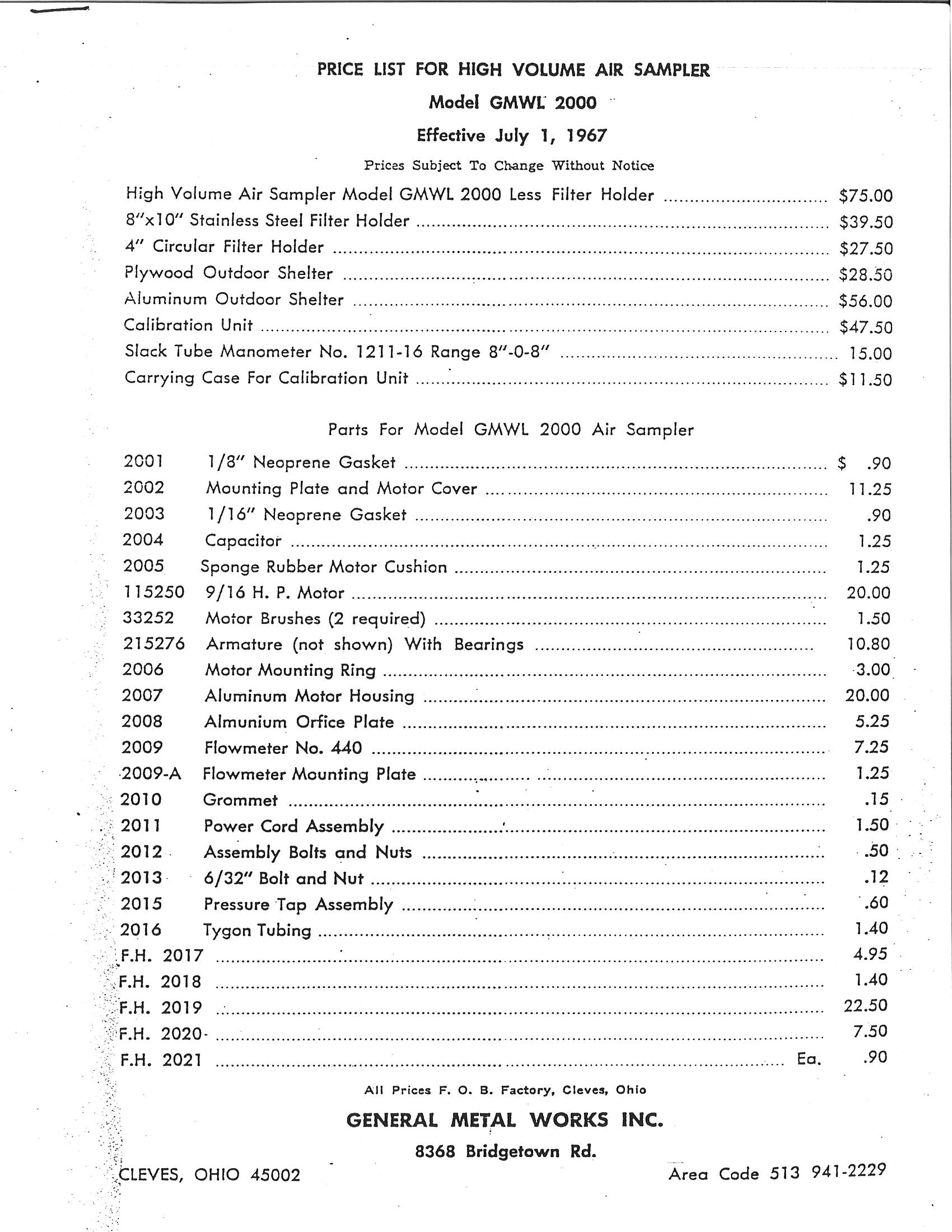

After only a few months of operating the business, Dr. Fodor from the United States Department of Public Health Service contacted Web to fabricate a filter holder. He did not have the specified galvanized steel material in stock and chose to fabricate the filter holder from stainless steel. Dr. Fodor was pleased by the craftsmanship and was surprised it could be made from stainless steel. The choice of stainless steel proved to be a wise decision as this material outperformed the prototype made from galvanized steel which eventually rusted. Soon after, Dr. Fodor returned to GMW with a prototype blower motor assembly and asked that GMW build this product as well. As the story goes, my grandpa reviewed the prototype and noticed a tag “patent applied for” on it. Being a new business owner, this tag concerned him so much that he went back to the Department of Health where he and Dr. Fodor called the United States Patent Office in Washington DC. After an hour of discussion the matter was settled, and it was decided that this product could not be patented because it was a Government design. GMW designed and built a production model of the blower motor assembly and were well on their way to producing the first Total Suspended Particulate (TSP) High Volume Air Sampler. It was given the name Model 2000 which, at the time seemed to be a futuristic model number. These early TSP samplers featured wooden shelters eventually produced by my maternal Grandfather Ervin who operated a wood shop. Although modern High Volume Air Samplers employ advanced controls, they still feature the stainless steel filter holders, blower motors and shelters originally produced by our family business.

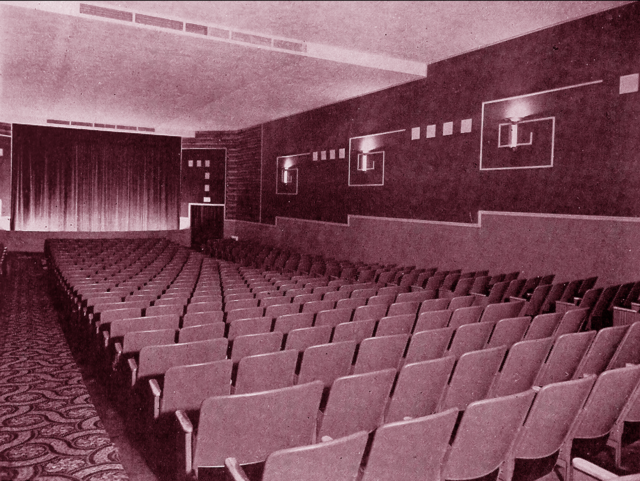

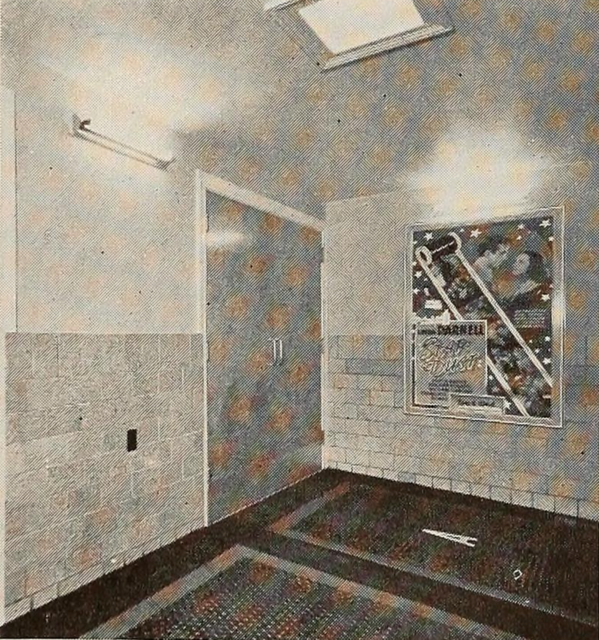

Fast forward to 1960 when orders for TSP samplers systems were arriving every week. By 1965 competitors began showing up. All of them eventually failed as a result of the hard work, good quality, low prices and persistence of the Tisch family. Between 1965 and 1968 GMWs sheet metal fabrication business and the air sampler business grew until it became necessary to split off the Air Sampling Division of GMW in 1968. My Father headed up the Air Sampling Division with a staff of four. They set up shop in a rented building 2 miles away. Dad’s air sampling division of GMW experienced explosive growth during this time and they quickly outgrew their rented space. Around 1970, they introduced the aluminum shelter that is still used to this day. That same year the United States Environmental Protection Agency was founded, and the family purchased the Cleves town theater for conversion into a production facility. Although I was 9 years old, I have good memories of the Avalon Theater with its slanted floor, red velvet chairs, the projector room, and the massive construction effort to transition the building into a factory and office. Business was good and continued to grow as the TSP sampler gained popularity and advanced features such as flow control, elapsed timers and flow recording capabilities. Like Dad, Jim Tisch and I got our first jobs with GMW as teenagers.

In 1980 the neighboring butcher shop came up for sale, was purchased and a high bay 6,000 square foot building was added onto the existing facility making a total of 13,000 square feet available to build and sell air samplers. During this period of expansion for GMW, the EPA was developing regulation for measuring breathable or respirable particulate matter 10 microns in aerodynamic diameter and below namely, PM10. GMW found themselves in the middle of this development and were seen as pioneers in the industry. Others noticed the potential for air pollution monitoring using the high volume method and competition was sprouting up. Andersen Instruments began buying companies starting with Sierra Instruments in Carmel Valley, CA in 1981 and eventually GMW in 1983 essentially owning the entire high volume air sampler market. Since that day in 1983 when Andersen Instruments bought the family business, Andersen Instruments/GMW had been transferred or sold 7 times through the late 80s into the 1990s when Thermo Environmental eventually bought them and dropped the name GMW all together. By the late 1990s Thermo had laid off all the local staff and moved production to Atlanta.

Jim Tisch and I founded Tisch Environmental, Inc. (TEI) in February of 1998. Within a year, Dad joined the company and our Brother Bob eventually joined in 2012. It was a “my three sons” dream come true for Dad who worked side by side with his three boys until his retirement in 2000. Bob’s middle Daughter Gabriele Tisch started with the company in 2014 making four consecutive generations of Tisches producing air quality instrumentation all starting with Grandpa in his sheet metal shop 70 years ago.

TEI’s first inventory location was my personal workshop where we packed and shipped our first orders from. We learned that the former GMW production facility was put onto the market and, like Grandpa, we were in the right place at the right time and were able to buy it. We moved all of my tools and our meager inventory from my workshop into the former GMW production facility. The building seemed massive at the time. We followed our business plan, was granted a SBA loan, found a bank willing to work with us, set up business systems, maintained a tight budget, learned how to generate payroll, withheld taxes, acquired health insurance, hired our first employee, and worked many times around the clock. It was the time of our lives. We worked feverishly developing our version of the high volume air sampler and within a few months had a couple of hand-made prototypes we showed off in San Diego at a trade show. Customers bought all the products we had at the show right off of the trade show floor. We came home empty handed with big smiles on our face ready to reproduce the products we had sold. Soon to follow was our version of the TSP sampler, semi-volatile vapor samplers, acid rain samplers and cotton dust samplers. Next we added industrial hygiene samplers then viable and non-viable impactors. We were listening to the needs of our customers and routinely adding new products to our portfolio.

In 2000 one of our customers became aware that Mr. Troy Todd of AADCO Instruments was losing his sight and inquired if TEI could contact Troy to build and supply the products he made. I contacted Troy, and soon after, Jim, John, Dad and Fred Taphorn (TEI’s first employee) purchased his company Advanced Analytical Device Company or AADCO Instruments. Troy visited the Cincinnati Eye Institute and with treatment regained his eyesight and enjoyed his last year working by teaching us all about AADCO Instruments. AADCO Instruments premier product was the Zero Air Generator (ZAG). The ZAG is used to produce purified air that can provide a zero calibration point for gas analyzers or mixed with calibration gases at various concentration to produce a calibration curve for these gas analyzers. In 2002, the AADCO Instruments lie of products were incorporated into the Tisch Environmental portfolio.

In 2002 Tisch Environmental received official recognition from the United States EPA in the form of Federal Reference Method (FRM) for our high volume 6XXX series PM10 product. This FRM status is very valuable to sell into International markets. By this time, we had a growing list of satisfied and loyal customers, we attended all the important trade shows with our expanding product lines, our philosophy of same day shipping was becoming well known, our practices of answering phone calls with a live voice was appreciated and providing quick responses to emails was paying off. International distributors were contacting us to represent our products. We were not only paying off our long term debt ahead of schedule, we were bringing together a highly skilled staff of professionals and we were building a brand name that was noticed by everyone in the business.

TEI began production of passive samplers as a result of a customer reaching out and looking for a reliable supply of high quality, fairly priced and effective samplers. The customer was Dr. Tom Harner of Environment Canada. Dr. Harner and his crew of scientists have suggested sampler designs, developed the procedures for sample collection, deployed network(s) of samplers around the world, studied/documented the processes/procedures and presented scientific papers on their work so others could duplicate their success. Environment Canada and TEI continue as partners and have formed a lasting relationship.

In 2007 TEI formed a new division called Tisch Scientific (TS). The original intention of TS was to create a completely different set of customers/suppliers aside from TEI’s. We started by reselling filtration products using an e-commerce platform. The web site we chose was scientificfilters.com. TS has grown from two founding employees operating in a warehouse to an 8 person staff and 6000 SF of inventory in 17 years of operation. Currently, 35-40% of our total revenue is generated by TS. We have earned business from thousands of unique customers, and we ship hundreds of shipments weekly.

In 2008 the US Congress promulgated new legislation for the EPA that resulted in an addition of Pb-lead to the list of criteria pollutants. At the same time EPA lowered the regulations for Pb in ambient air by a factor of 10 and chose the High-Volume Air Sampler method as the reference for measuring for Pb in air. Just when the opponents and critics of the high-volume air sampler were celebrating its demise, the EPA breathed life back into it with this new regulation.

In 2011, TS outgrew their warehouse space and moved to an empty shopping center in North Bend, OH. When Bob Tisch joined the company, he also located his office at the North Bend facility. TS, TEI Engineering, Product Development and new product manufacturing also filled this 11,000 SF space.

In 2014 TEI received additional recognition from the US EPA in the form of FRM status of our low volume platform for three size fractions of particulate matter PM10, PM2.5 and PMc (coarse=PM10-PM2.5). The product was named to honor my Father Wilbur P. Tisch and is simply called “the Wilbur” or part number TE-WILBUR. A recent addition to our product line is a calibrator for the Wilbur and other low volume products named TE-PRO-CAL.

In January of 2022 all operations in North Bend were moved to Cleves into our new 20,000 SF facility directly next door to our primary facility. Now, for the first time in 15 years, all of our staff are in the same place, on one campus all with the same phone system and mere walking distance from each other.

In 2012 CDC/NIOSH (Center for Disease Control/National Institute of Occupational Safety and Health) was looking for a firm to commercialize a product they had developed. Dr. Bill Lindsley inquired if we would acquire patent rights and commercialize their product. After working with the government technology transfer representatives, no deal was ever made. Fast forward eight years to 2020, Dr. Lindsley re-connected and shared that he and his colleagues were close to retirement and wanted their work to be available to the public. TEI was the only firm willing to accept this public offering. We gathered what knowledge we could from them, developed the means to manufacture and introduced the TE-BC251 bio-aerosol collector to the market. The TE-BC251 is a wearable multi-stage bio-aerosol collector used for the collection of airborne viruses including INFLUENZA and COVID-19.

From meager beginnings in 1954 when Grandpa produced a filter holder and blower motor assembly, through four generations of the Tisch family producing air quality measurement instrumentation for 70 years, we have truly enjoyed success on every level we could have imagined. Over the 25 years TEI has been in existence, many have approached us in hopes of partnering with or buying part or all of the business. We have successfully avoided selling out or becoming an acquisition of a firm that does not know or care about our family or the other families that make up our staff. I have often said “TEI is a family business and also a business of families”. That being said, I was most proud to announce in 2023 that TEI has become an employee-owned company in the form of an ESOP (Employee Stock Ownership Plan). An ESOP is an employee benefit plan that gives workers ownership interest in the company in the form of shares of stock. TEI founders Jim and I now sit on the BOD and are working toward retirement within the next couple of years. The ESOP reduces the chances of TEI being sold off to corporate greed and makes us all proud to know we are leaving a legacy for future generations. We are currently developing a strategic plan to grow the business via new streams of revenue and new product offerings to make lasting and significant improvements to the air quality around the world.

-Signed, W. John Tisch

Photos

Timeline

- 1954: Web Tisch buys General Metal Works, Inc. (GMW) in Greendale, Indiana.

- 1950s-1960s: GMW fabricates stainless steel filter holders and blower motor assemblies for the United States Department of Public Health Service, leading to the development of the first Total Suspended Particulate (TSP) High Volume Air Sampler, named Model 2000.

- 1965: Air Sampling Division splits off from GMW due to rapid growth, led by Web Tisch’s son, Will Tisch

- 1970: Introduction of aluminum shelter for air samplers and formation of the United States Environmental Protection Agency. The Avalon Theater is purchased for conversion into production facility for GMW.

- 1980: Expansion with the purchase of neighboring butcher shop and addition of a high bay building.

- 1983: Acquisition of GMW by Andersen Instruments, marking the start of several ownership changes.

- 1990s: GMW, a subsidiary of Andersen Instruments, was transferred/sold several times. In the late 90s, Thermo Environmental purchases GMW, lays off local staff and moves production to Atlanta.

- 1998: W. John Tisch and Jim Tisch found Tisch Environmental, Inc. (TEI)

- 2000: Purchase of AADCO Instruments, adding Zero Air Generator (ZAG) to product portfolio.

- 2002: TEI receives Federal Reference Method (FRM) status from the United States EPA for high volume 6XXX series PM10 product.

- 2007: Formation of Tisch Scientific division for reselling filtration products.

- 2008: EPA regulation adds lead (Pb) to criteria pollutants, reviving interest in high-volume air samplers.

- 2011: Tisch Scientific relocates to a larger space in North Bend, Ohio.

- 2014: TEI receives FRM status for low volume platform for PM10, PM2.5, and PMc.

- 2022: Consolidation of all operations. Tisch Scientific and ISO Tisch Environmental relocates to Cleves into a new 20,000 SF facility.

- 2021: Introduction of TE-BC251 bio-aerosol collector for airborne virus collection due to Coronavirus Pandemic

- 2023: TEI becomes a 100% employee-owned and operated company through an ESOP (Employee Stock Ownership Plan).

Get Social